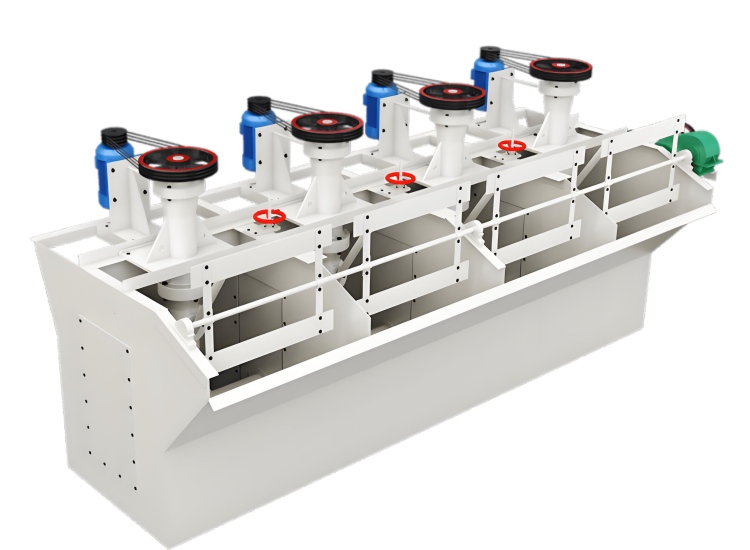

A flotation machine is an essential industrial device used to separate valuable minerals from ore by leveraging differences in their surface hydrophobicity. It employs aeration and agitation to create bubbles that selectively attach to target mineral particles, floating them to the surface for collection. Widely utilized in mining, metallurgy, and wastewater treatment, this equipment ensures efficient mineral recovery, high processing capacity, and adaptability to various ore types, including copper, gold, lead-zinc, and coal.

Precision control ensures maximum mineral extraction.

Optimized design reduces power consumption.

Corrosion-resistant materials (e.g., rubber-lined tanks, stainless steel components) for longevity.

Available in mechanical, pneumatic, or column flotation models.

Integrates with sensors and control systems for real-time adjustments. Low Maintenance: Modular design simplifies part replacement and upkeep.

| Specification | Effective volume (m³) | Productive capacity (m³/min) | Power (Impeller motor/Scraper motor) KW | Weight (t/Single trough) |

|---|---|---|---|---|

| XJK-0.35(3A) | 0.35 | 0.18-0.4 | 1.5/1.1 | 0.43 |

| XJK-0.62(4A) | 0.62 | 0.3-0.9 | 3/1.1 | 0.86 |

| XJK-1.1(5A) | 1.1 | 0.6-1.6 | 5.5/1.1 | 1.38 |

| XJK-2.8(6A) | 2.8 | 1.5-3.5 | 11/1.1 | 2.33 |

| XJK-5.8(7A) | 5.8 | 3-7 | 22/1.5 | 3.533 |

Mineral Processing : Separating sulfide ores (e.g., copper, gold, silver) from gangue.

Coal Industry : Removing impurities from coal fines.

Metallurgy : Recovering valuable metals from slag or tailings.

Wastewater Treatment : Removing suspended solids and oils from industrial effluents.

-Chemical Industry : Purifying and concentrating chemical products.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.