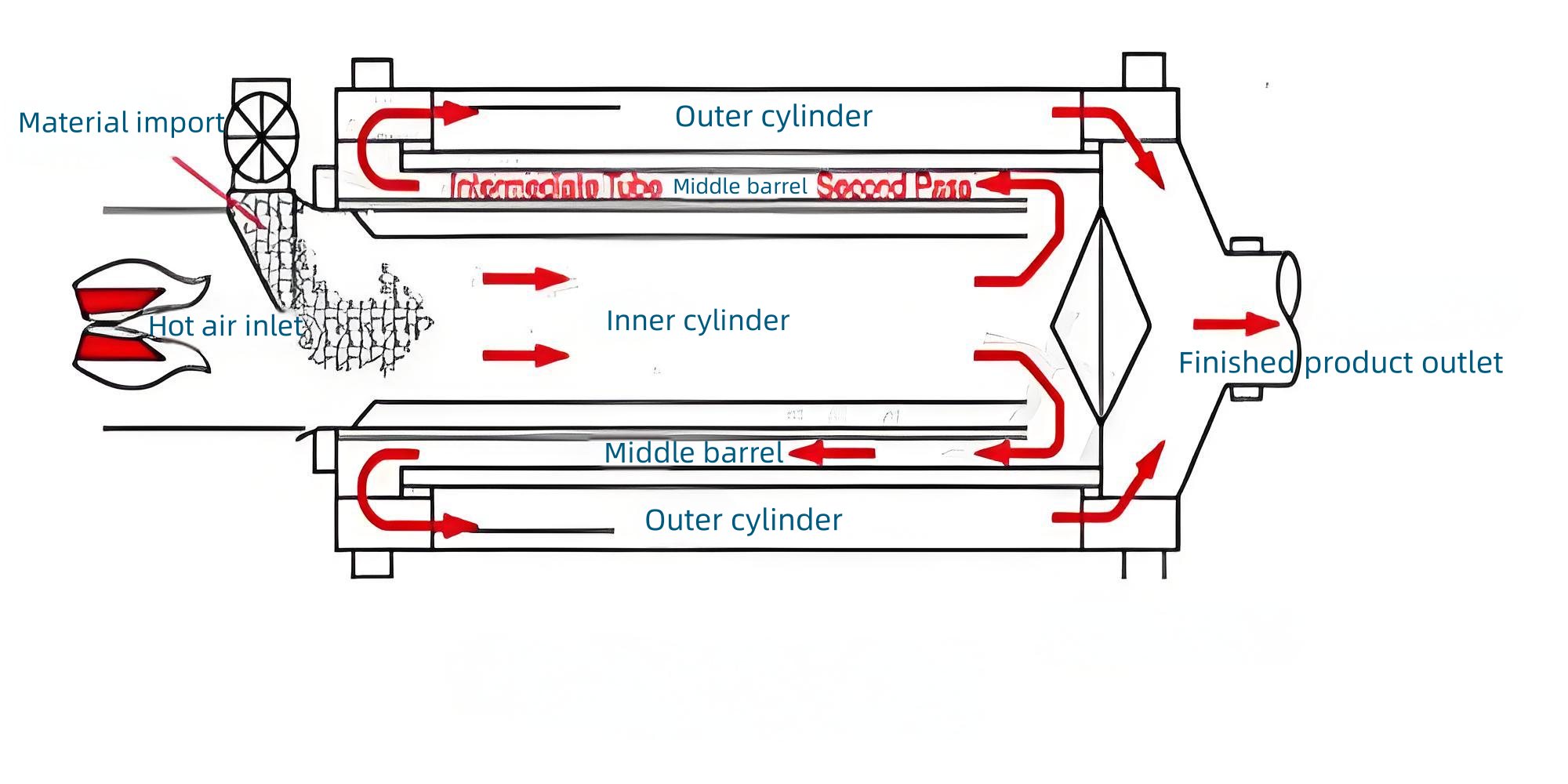

The Three Cylinder Sand Dryer is a high-efficiency industrial drying system engineered for rapid moisture removal from bulk materials. Its three-drum design enhances heat utilization, reduces energy waste, and ensures uniform drying across diverse materials, making it ideal for large-scale production environments.

Applicable materials:

River sand, dry mortar, yellow sand, cement factory slag, clay, coal gangue, mixed materials, fly ash, straw powder, wood chaff, etc.

Capacity: 5-90 t/h

Diameter:1.5-4.2 m

Length:3-8.5 m

Power: 4.4-74 kW

Weight: 6-70 Tons

Rotational speed: 2-7.5 r/min

Triple-stage drying minimizes heat loss, cutting energy costs by up to 30%.

Processes 3-90 tons/hour (customizable based on model).

Adjustable temperature, rotation speed, and airflow for optimal results.

Robust stainless steel construction resists corrosion and wear.

Compatible with biomass fuels; reduces carbon footprint.

| Model | Drum Speed (r/min) | Feedstock Moisture (%) | Discharge Moisture (%) | Capacity (T/h) | Power (kw) | Weight (t) |

|---|---|---|---|---|---|---|

| 1500×3000 | 2-7.5 | 10-25 | ≤1 | 5-8 | 2.2×2 | 8 |

| 1800×4000 | 2-7.5 | 10-25 | ≤1 | 10-15 | 3×2 | 13 |

| 2000×4500 | 2-7.5 | 10-25 | ≤1 | 15-20 | 4×2 | 15.8 |

| 2000×6000 | 2-7.5 | 10-25 | ≤1 | 15-22 | 5.5×2 | 20 |

| 2200×4500 | 2-7.5 | 10-25 | ≤1 | 18-25 | 5.5×2 | 18 |

| 2200×6000 | 2-7.5 | 10-25 | ≤1 | 20-30 | 7.5×2 | 22 |

| 2500×5500 | 2-7.5 | 10-25 | ≤1 | 25-32 | 11×2 | 27 |

| 2700×7000 | 2-7.5 | 10-25 | ≤1 | 25-35 | 7.5×4 | 30 |

| 3000×7000 | 2-7.5 | 10-25 | ≤1 | 30-40 | 7.5×4 | 33 |

| 3200×7000 | 2-7.5 | 10-25 | ≤1 | 40-50 | 11×4 | 36 |

| 3600×8000 | 2-7.5 | 10-25 | ≤1 | 50-70 | 15×4 | 50 |

| 4200×8500 | 2-7.5 | 10-25 | ≤1 | 70-90 | 18.5×4 | 70 |

- Agriculture : Drying grains, seeds, and crop residues.

- Chemical Industry : Processing powders, granules, and synthetic compounds.

- Mining & Minerals : Drying ores, sand, clay, and slag.

- Biomass & Waste Recycling : Preparing biomass pellets, sawdust, or municipal sludge for energy conversion.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.