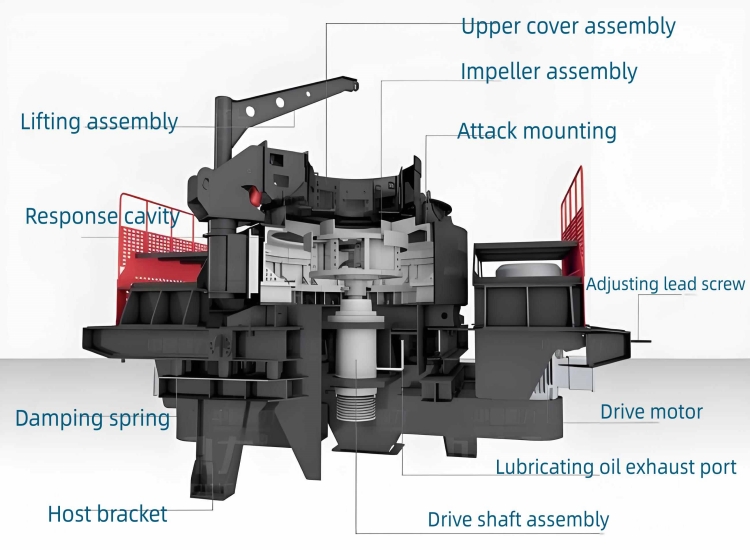

The Impact Sand Making Machine (Vertical Shaft Impact Crusher) is a high-efficiency crushing equipment designed to produce artificial sand and fine aggregates by utilizing a high-speed rotor to throw materials against impact-resistant plates. Ideal for processing hard and abrasive materials such as granite, basalt, quartz, and concrete, it delivers superior particle shape, consistent grading, and low operational costs. Widely used in construction, mining, and infrastructure projects, this machine excels in producing high-quality sand for concrete, asphalt, and industrial applications.

Capacity: 70-750 t/h

Feeding Size: ≤30-60 mm

Power: 150-630 kW

Rotational speed: 900-1900(r/min)

Lead Time: 15-30 Days.

Produces cubical-shaped aggregates ideal for concrete and asphalt.

Achieves fine crushing with low energy consumption.

Modular design allows quick replacement of wear parts (e.g., impact plates, rotor tips).

Reinforced alloy components and wear-resistant liners extend lifespan.

Adjustable rotor speed and impact plate gap accommodate diverse materials.

Low noise and dust emissions comply with environmental regulations.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 |

|---|---|---|---|---|---|

| Capacity (t/h) | 120-180 Cascade and Center Feeding | 200-260 Cascade and Center Feeding | 300-360 Cascade and Center Feeding | 450-520 Cascade and Center Feeding | 490-600 Cascade and Center Feeding |

| 60-90 Center Feeding | 100-130 Center Feeding | 150-190 Center Feeding | 225-260 Center Feeding | 250-310 Center Feeding | |

| Feeding Size (mm) | <35 Soft Material | <40 Soft Material | <45 Soft Material | <50 Soft Material | <50 Soft Material |

| <30 Hard Material | <35 Hard Material | <40 Hard Material | <45 Hard Material | <45 Hard Material | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*22278 | 5000*2700*3300 | 5100*2790*3320 |

| Power Source | 380V:50hz | ||||

| Vibrating Sensor | Inspection Scope: 0.1-20mm/s, it can be adjusted continuously. | ||||

| Hydraulic Lubrication Station | Power of Double Oil Pump: 2*0.31 kw | ||||

| Safety | Double oil pumps ensure supply of oil; Stop automatically without oil flow or oil pressure; Water cooled; Heating starts the motor in winter. | ||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | ||||

| Power of Oil-Box Heater | 2KW | ||||

Artificial Sand Production: Converts stones into high-quality sand for construction and industrial use.

Aggregate Processing: Crushes rocks into uniformly shaped gravel for concrete and asphalt mixtures.

Mining & Quarrying: Processes ores, minerals, and hard stones into fine particles.

Recycling: Repurposes construction waste (e.g., concrete, bricks) into reusable materials.

Road Construction: Produces durable base and surface materials for highways.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.