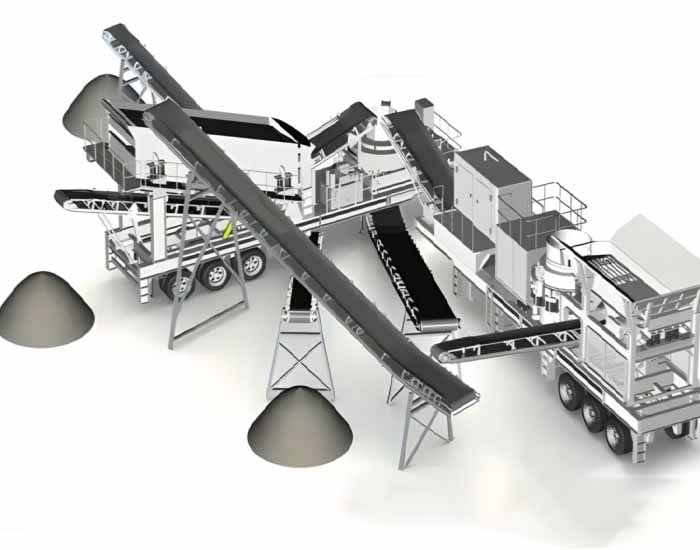

The Mobile Crushing and Sand Making Machine is a versatile, modular-designed equipment that integrates crushing, screening, and sand-making functions into a single mobile unit. It can be flexibly configured with various crushers (e.g., jaw crusher, hammer crusher, impact crusher/sand maker) and sand-making modules to meet diverse material processing needs. Powered by a diesel generator, it operates independently of external power sources, making it ideal for remote or temporary sites. Available in tire-mounted or track-mounted versions, this machine combines portability, high efficiency, and adaptability for construction, mining, recycling, and infrastructure projects.

Model: 800×800

Roller diameter (mm): 800

Roller length (mm): 800

Capacity (t/h): 70-100

Feedstock size (mm): ≤600

Customize with jaw, hammer, or impact crushers and sand-making units for varied materials (hard rock, concrete, etc.).

No reliance on grid power; suitable for off-grid operations.

Choose tire-mounted (for highway transport) or track-mounted (for rough terrain) mobility.

Pre-assembled modules reduce installation time and costs.

| Model | Funnel Size (mm) | Best Feedstock Size (mm) | Production Capacity (t/h) | Motor Power (kw) | Weight (Motor included) (kg) | Overall Dimension (mm) |

|---|---|---|---|---|---|---|

| GZD850×3000 | 850×3000 | 400 | 80-120 | 7.5 | 3900 | 3110×1800×1600 |

| GZD960×3800 | 960×3800 | 500 | 120-210 | 11 | 4200 | 3850×1950×1630 |

| GZD1100×4200 | 1100×4200 | 650 | 180-400 | 15 | 4800 | 4400×2050×1660 |

| GZD1100×4900 | 1100×4900 | 650 | 250-480 | 15 | 5300 | 5200×2050×1700 |

| GZD1300×4900 | 1300×4900 | 800 | 300-550 | 22 | 6700 | 5200×2350×1750 |

| GZD1300×6000 | 1300×6000 | 800 | 400-800 | 30 | 7800 | 6082×2580×2083 |

| GZD1500×6000 | 1500×6000 | 1020 | 500-900 | 30-45 | 10300 | 6160×2918×2292 |

| Roller Diameter (mm) | Roller Length (mm) | Capacity (t/h) | Feedstock Size (mm) | Power (kw) |

|---|---|---|---|---|

| 800 | 800 | 70-100 | ≤600 | 55-75 |

| 1000 | 1000 | 90-120 | ≤800 | 55-75 |

| 1200 | 1200 | 130-160 | ≤900 | 75-90 |

| 1400 | 1400 | 190-210 | ≤1000 | 132-150 |

| 1600 | 1600 | 250-300 | ≤1000 | 160-210 |

| 1800 | 1800 | 300-400 | ≤1200 | 180-320 |

- Construction Sites: On-site crushing of concrete, bricks, and asphalt for reuse.

- Mining & Quarrying: Processing ores, rocks, and aggregates in remote locations.

- Road Building: Producing gravel and sand for base and surface layers.

- Demolition Recycling: Repurposing waste materials into reusable aggregates.

- Emergency Projects: Rapid deployment for disaster recovery or temporary operations.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.