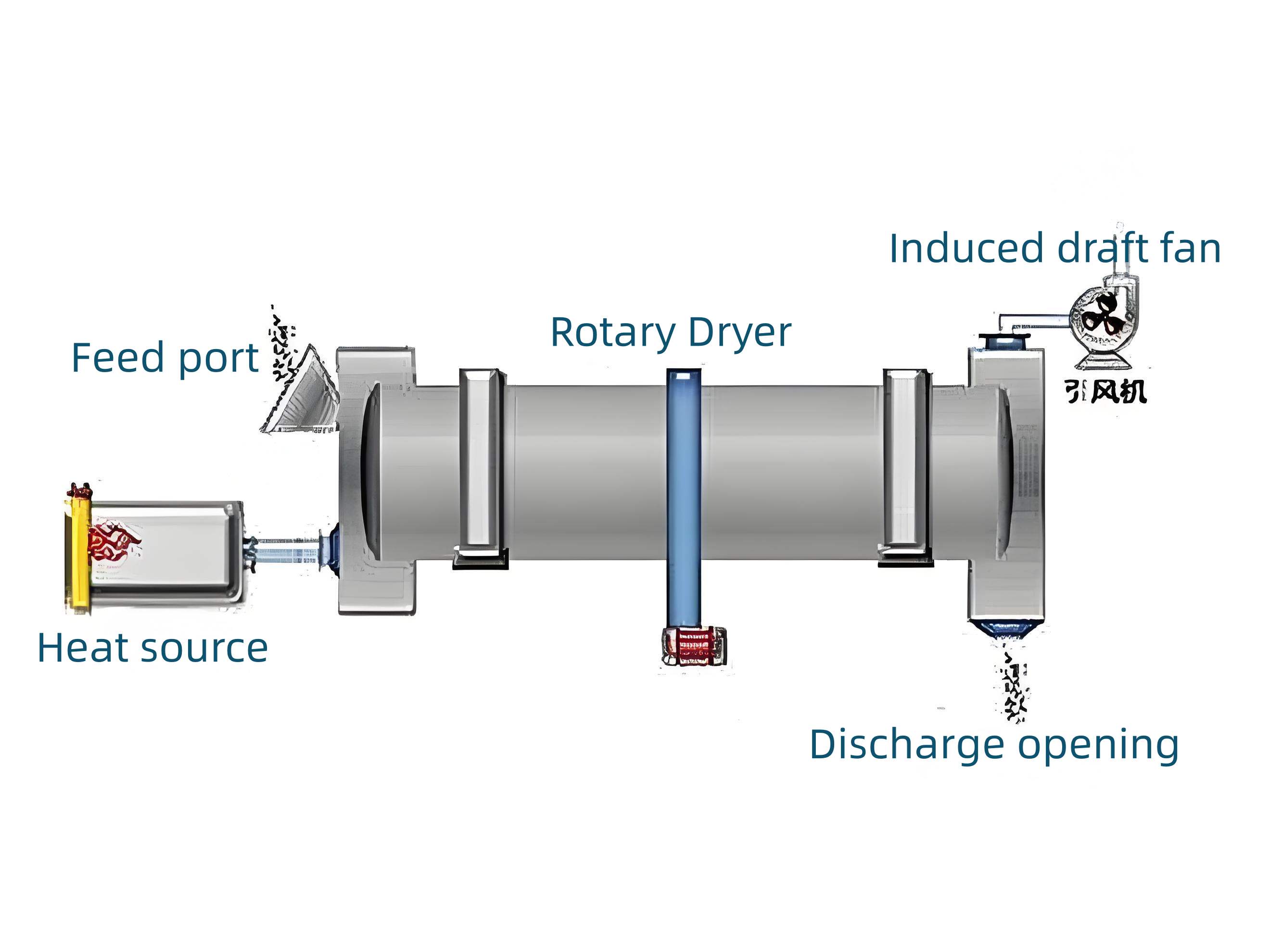

The lifting device is welded inside the Rotary Dryer, and the material moves slowly under the rotating action of the cylinder, and automatically moves from the feed end to the discharge end. The cylinder body capacity is large, can handle a large number of materials at one time. The centralized control system can realize the intermediate monitoring and management and reduce the labor cost

Rotary Dryer can handle a variety of materials, including dry and wet materials, the cylinder is made of corrosion-resistant wear-resistant material, and stainless steel can also be used according to demand to meet the needs of different industries, different humidity at one time drying.

Rotary Dryer adopts pin replaceable gear instead of traditional cast steel gear, saving cost investment, greatly reducing maintenance costs and time, the overall design is simple and reliable.

Rotary dryer can use a variety of heat sources, including coal, steam, natural gas, biomass particles, heavy oil and other fuels to meet the different needs of users.

| Model | Gradient (%) | Rotate Speed (r/min) | Air Inlet Temperature (℃) | Power (kw) | Capacity (t/h) | Weight (t) | Remarks |

|---|---|---|---|---|---|---|---|

| WSH-600 | 1-3 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 | Capacity is related to the thermal process |

| WSH-800 | 1-3 | 3-8 | ≤700 | 4 | 0.8-2.5 | 3.5 | |

| WSH-1000 | 1-3 | 3-8 | ≤700 | 5.5 | 2.0-4.5 | 5.6 | |

| WSH-1200 | 1-3 | 3-8 | ≤700 | 7.5 | 4-8 | 14 | |

| WSH-1500 | 1-3 | 2-6 | ≤800 | 15 | 5-15 | 17.8 | |

| WSH-1800 | 1-3 | 2-6 | ≤800 | 18.5 | 10-20 | 22 | |

| WSH-2000 | 1-3 | 1.5-6 | ≤800 | 22 | 12-30 | 28 | |

| WSH-2200 | 1-3 | 1.5-6 | ≤800 | 30 | 15-35 | 36 | |

| WSH-2400 | 1-3 | 1.5-5 | ≤800 | 37 | 20-50 | 52 | |

| WSH-3000 | 1-3 | 1.5-5 | ≤800 | 75 | 25-75 | 65 | |

| WSH-3200 | 1-3 | 1.5-5 | ≤800 | 90 | 25-90 | 75 |

Chemical Industry

Catalyst Drying: Industrial Rotary Dryers can be used to precisely dry catalysts, remove moisture and impurities, ensure catalyst performance, and improve the efficiency and selectivity of chemical reactions.

Fertilizer Production: In the process of fertilizer manufacturing, such as urea and compound fertilizer, raw materials or semi-finished products need to be dried. For example, in urea production, the urea solution is evaporated and concentrated, and then further dried by a Rotary Dryer to form a granular urea product for easy storage and transportation.

Building Materials Industry

Gypsum Board Production: In the production process of gypsum board, the gypsum slurry needs to be dried and formed. Industrial Rotary Dryers can quickly remove moisture from gypsum slurry, so that the gypsum board meets the specified moisture content and strength requirements, and improve the production efficiency and quality of gypsum board.

Ceramic Raw Material Drying: Rotary Dryers can dry ceramic raw materials to a suitable humidity, which is convenient for subsequent blank making, molding and firing processes, and helps to improve the quality of ceramic products and reduce defects such as cracking during firing.

Mining industry

Coal drying: Industrial Rotary Dryers can dry coal, reduce the moisture content of coal, increase the calorific value of coal, make it easier to transport and sell, and also reduce the risk of spontaneous combustion of coal during storage.

Non-metallic mineral drying: Rotary Dryers can meet the drying needs of non-metallic minerals such as graphite, kaolin, bentonite, etc., and improve the quality and added value of products.

Papermaking industry

Pulp drying: Industrial Rotary Dryers can efficiently dry pulp to achieve the appropriate dryness to increase the dryness of pulp, facilitate subsequent papermaking and provide papermaking machines with stable quality pulp.

Paper drying: After papermaking, paper still contains a high amount of moisture and needs further drying to meet the quality requirements of finished paper. Rotary Dryers can dry paper evenly and quickly, improve the strength, flatness and glossiness of paper, and improve the physical properties and appearance quality of paper.

Metallurgical industry

Metal powder drying: Industrial Rotary Dryers can remove moisture and volatile impurities from metal powders such as iron powder and copper powder, prevent metal powder oxidation and agglomeration, improve the quality of metal powder, and meet the requirements of processes such as powder metallurgy.

Metallurgical waste slag treatment: Drying metallurgical waste slag with a Rotary Dryer can reduce the water content of the waste slag, facilitate subsequent waste slag treatment and resource recycling, and reduce pollution to the environment.

Environmental protection industry

Sludge drying: Industrial Rotary Dryers can dry sludge, reduce the water content of sludge to a certain extent, reduce the volume and weight of sludge, and facilitate subsequent sludge landfill, incineration or resource utilization.

Refuse-derived fuel (RDF) drying: Industrial Rotary Dryers can be used to dry refuse-derived fuel, improve its calorific value and combustion efficiency, make it more suitable for use as fuel, and achieve waste reduction and resource utilization.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.