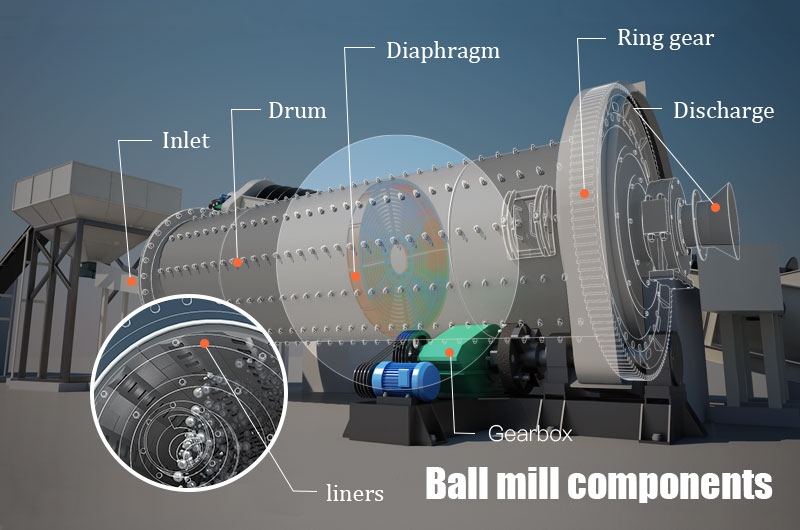

Ball mill is a common grinding equipment, but also an important core equipment in mineral processing operations. Ball mills are suitable for grinding various ores and other materials. They are widely used in mineral processing, building materials and chemical industries.

Capacity: 1-80 t/h

Feeding Size: ≤20-25 mm

Discharging size:0.074-0.89 mm

Power: 18.5-430 kW

Weight: 4.6-102 Tons

Ball load: 1.5-48 Tons

A new type of ball mill designed according to a new concept, using special rolling bearings as the support structure of the cylinder body.

Made of high wear-resistant materials, with a long maintenance cycle and cost savings.

cement ball mill, cone ball mill, energy-saving ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill

excellent product quality, reliable and durable, reducing customer operating and maintenance costs

| Model | Rotate Speed (r/min) | Ball Weight (t) | Feedstock Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

|---|---|---|---|---|---|---|---|

| φ900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| φ900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| φ1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| φ1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| φ1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| φ1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| φ1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| φ1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| φ1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| φ1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| φ1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 180 | 34 |

| φ1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 210 | 36 |

Ball mills are versatile grinding equipment widely applied in multiple industrial sectors. Here are the key application fields and processed materials:

1. Industrial Applications:

Mining & Metallurgy:

- Ore processing (iron, copper, gold, zinc)

- Coal pulverization

- Precious metal extraction

Cement Industry:

- Clinker grinding

- Limestone/gypsum processing

Ceramics & Glass:

- Raw material preparation (feldspar, quartz, clay)

- Glaze production

Chemical Industry:

- Fertilizer manufacturing

- Pigment dispersion

- Explosives processing

Power Generation:

- Coal pulverization for thermal plants

- Fly ash grinding

Advanced Materials:

- Nanomaterial synthesis

- Battery material processing (cathode/anode powders)

2. Processed Materials:

-Metallic Substances: Iron ore, copper concentrate, aluminum powder

- Non-Metallic Minerals: Limestone, silica sand, marble, granite

- Industrial Compounds: Cement clinker, slag, ceramics raw mix

- Chemical Products: Pesticides, dyes, carbon black

- Energy Materials:Coal, petroleum coke, biomass

- Recyclables: Electronic waste, construction debris

- Specialty Materials:Pharmaceuticals, food additives (GMP-compliant models)

Technical Advantages:

- Dry/wet grinding modes

- Closed-circuit grinding systems

- Ultrafine grinding (<10μm)

- High-hardness material processing

- Contamination-sensitive applications (ceramic-lined models)

- Modern ball mills integrate IoT monitoring and adjustable rotation speeds (15-30 RPM) to meet diverse industrial requirements from coarse grinding to nanoparticle production.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.