Rotary kiln refers to rotary calcining kiln, which belongs to the category of building materials equipment. It can be divided into cement kiln, metallurgical chemical kiln and lime kiln according to the different materials handled.

Applicable materials:

Cement, Lime, Depleted Iron Ore, Chromite, Nickel Iron Ore, Coconut shell, High Bauxite, Chromite, Chromite Powder, etc.

Capacity: 2.5-200 t/h

Diameter:1.9-4.8 m

Length: 28-74 m

Power: 30-630 kW

Weight: 53-840 Tons

Rotational speed: 0.3-4 r/min

Continuous operation, suitable for large-scale production, optimized design of heat recovery process, and reduced energy consumption.

The refractory lining cylinder can withstand extreme temperatures and wear, with a strong structure and long service life.

Suitable for processing materials and processes (such as oxidation and reduction) of various materials such as powder, granules, and blocks.

Integrated temperature and pressure sensors and DCS systems to monitor and adjust process parameters in real time to ensure stable and safe operation.

Modern pollution control technologies (such as dust collectors and exhaust gas treatment devices) are used, with low emissions.

| Model (m) | Rotate Speed (r/min) | Gradient (%) | Output (t/h) | Reduction Drive Model | Velocity Ratio | Main Motor Model | Power (kw) | Rotate Speed (r/min) | Catch Wheel Form | Prop Up | Weight (t) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| φ1.9/1.6×36 | 0.53-1.59 | 4 | 2.5-3 | JZQ750-1 | 48.85 | JZT-72-4 | 30 | 1200/400 | Machine | 3 | 53 |

| φ2.1/1.8×36 | 0.5-1.51 | 4 | 4 | UT2-110 | 136.36 | JZS-81 | 30/10 | 1410/470 | Machine | 3 | 75 |

| φ1.2×35 | 0.5-1.6 | 3 | PM650 | 40.17 | JZTY71-4 | 22 | 1200/120 | Machine | 3 | 34 | |

| φ1.6×32 | 0.158-0.258 | 3 | PM750 | 48.57 | JZJY61-4 | 15 | 1200/120 | Machine | 3 | 46.82 | |

| φ1.8×45 | 0.66-1.98 | 4 | 3.5 | UT2-110 | 163.36 | JZS-81 | 30/10 | 1410/470 | Machine | 3 | 80 |

| φ2.2×50 | 0.125-1.25 | 3.5 | 4 | ZSI45-11 | 157 | YCT280-4A | 30 | 1320/132 | Machine | 3 | 130.71 |

| φ2.5×50 | 0.516-1.549 | 3.5 | 5.5 | ZSI65-7 | 99.96 | YCT355-4A | 55 | 1320/140 | Machine | 3 | 167.5 |

| φ3×48 | 0.3309-3.309 | 3.5 | 35 | ZI130-14 | 32.11 | ZSN4-250-21B | 90 | 1000/100 | Machine | 3 | 237 |

| φ3.2×50 | 0.398-3.975 | 3.5 | 50 | ZI130-16 | 40.85 | ZSN4-280-11B | 190 | 1500/150 | Machine | 3 | 263 |

| φ3.3×52 | 0.391-3.91 | 3.5 | 50 | ZSY500-28 | 27.707 | ZSN-315-082 | 190 | 1000/100 | Machine | 3 | 280.8 |

| φ4×60 | 0.396-3.96 | 3.5 | 104 | ZSY630-35.5 | 34.601 | ZSN4-355-092 | 315 | 1000/100 | Hydraulic | 3 | 487.5 |

| φ4.2×60 | 0.4165-4.165 | 3.5 | 116 | ZSY710-35.5 | 35.526 | ZSN4-355-12 | 420 | 1000/100 | Hydraulic | 3 | 576.1 |

| φ4.3×62 | 0.398-3.98 | 3.5 | 125 | ZSY710-35.5 | 35.714 | ZSN4-355-12 | 420 | 1000/100 | Hydraulic | 3 | 598.5 |

| φ4.8×74 | 0.35-4 | 4 | 208 | JH710C-SW305-40 | 42.226 | ZSN4-400-092 | 630 | 1500/130 | Hydraulic | 3 | 841 |

1. Cement industry

Clinker production: The rotary kiln is the core equipment of cement production. It is used to calcine raw materials such as limestone and clay at a high temperature of about 1450℃ to produce cement clinker (the main component is calcium silicate).

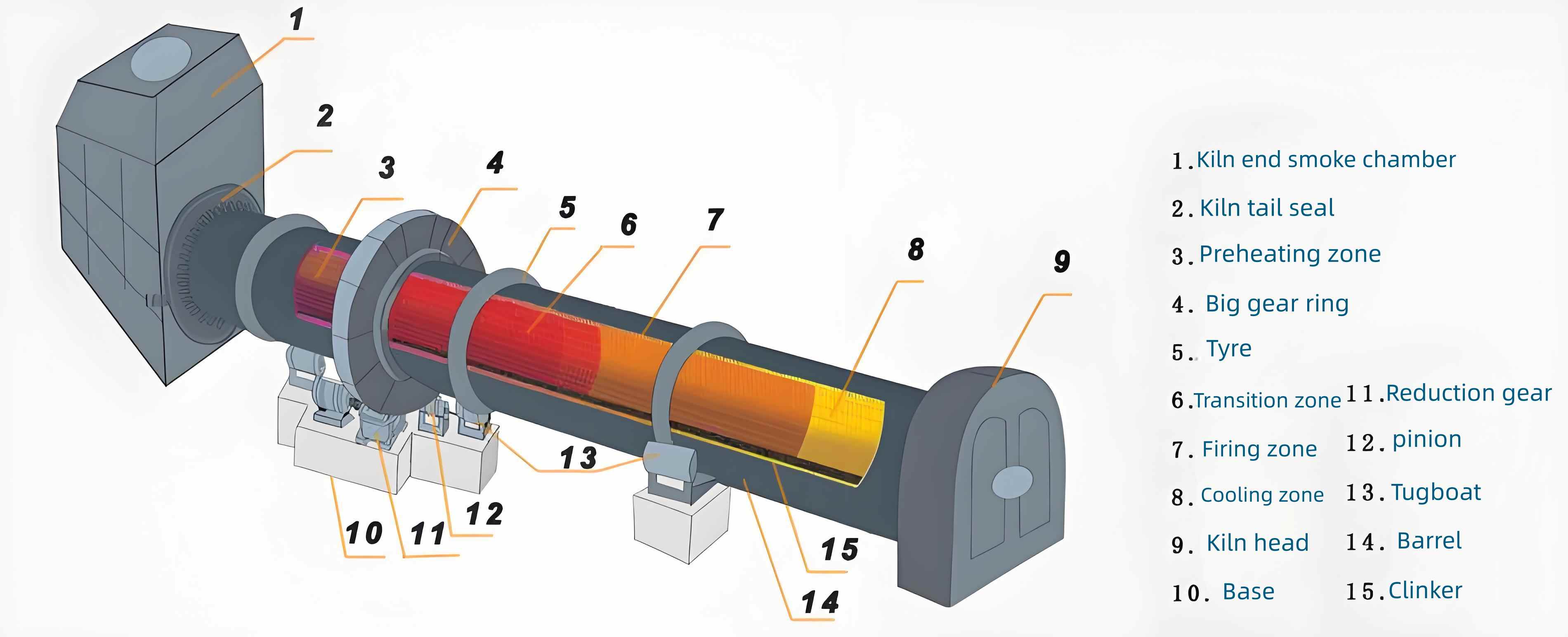

Process steps: drying, preheating, decomposition (carbonate decomposition), sintering and cooling.

2. Metallurgical industry

Alumina production: Calcination of aluminum hydroxide (Al(OH)₃) to produce alumina (Al₂O₃), which is used for electrolytic aluminum.

Iron ore treatment Magnetization roasting: Convert weakly magnetic hematite (Fe₂O₃) into strongly magnetic magnetite (Fe₃O₄) for magnetic separation.

Direct reduced iron (DRI): Use coal or natural gas to reduce iron ore to produce sponge iron (used for electric arc furnace steelmaking).

Other metals:

Roasting molybdenum concentrate, zinc ore, lead ore, etc., desulfurization or oxidation.

Ilmenite (FeTiO₃) is calcined to produce artificial rutile (TiO₂).

3. Chemical industry

Activated carbon production: Carbon-containing materials (such as coconut shells, coal) are made into porous structures through high-temperature activation (800–1000°C).

Catalyst preparation: Calcination of catalyst carriers (such as alumina, molecular sieves) to enhance activity.

Carbonate decomposition: Calcination of chemical raw materials such as barium carbonate and strontium carbonate.

Petroleum coke calcination: Remove volatiles, increase carbon content, and use it as an anode for aluminum electrolysis.

4. Environmental protection and waste treatment

Hazardous waste incineration: Treatment of medical waste, organic solvents, oily sludge, etc., high temperature (above 1200°C) to decompose toxic substances (such as dioxins).

Contaminated soil remediation: Pyrolysis of pollutants such as petroleum hydrocarbons and pesticides in the soil.

Municipal waste incineration: Some processes are used for incineration power generation or resource processing.

5. Building materials and refractory materials

Lime production: calcining limestone (CaCO₃) to produce quicklime (CaO), which is used in the steel, construction and other industries.

Ceramic aggregate preparation: expanded clay, shale, etc. are made into lightweight aggregates for concrete.

Refractory material calcination: such as calcining high-alumina bauxite, magnesia, etc.

6. Other applications

Mineral processing: calcination and modification of bentonite and kaolin to improve adsorption or whiteness.

Pigment production: calcination and surface treatment of titanium dioxide (TiO₂).

Nuclear waste solidification: high-temperature solidification of radioactive waste.

Advantages of rotary kiln

Strong adaptability: can process various forms of materials such as blocks, powders, and slurries.

High temperature stability: high temperature resistance (up to 1600℃), suitable for complex chemical reactions.

Continuous production: high degree of automation and large processing capacity.

Environmentally friendly and controllable: equipped with waste heat recovery and exhaust gas purification systems to reduce energy consumption and pollution.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.