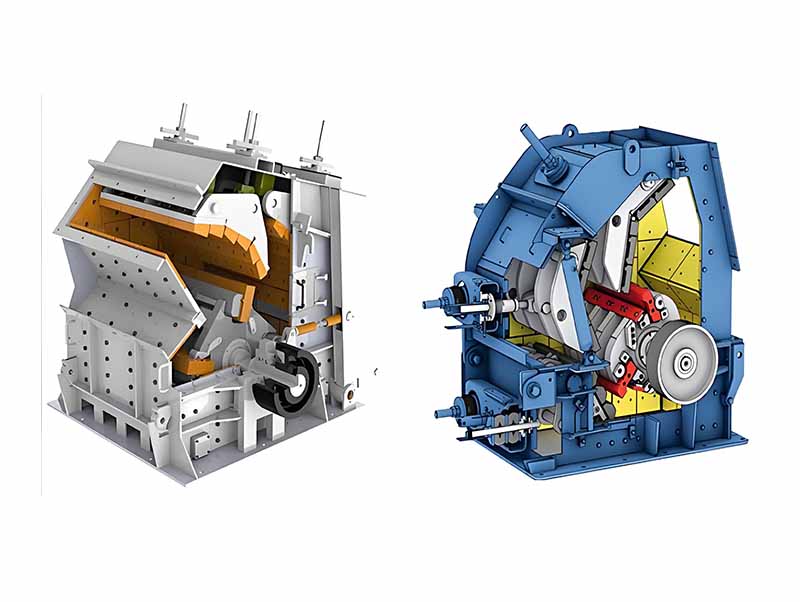

The impact crusher has the characteristics of simple design, reliable structure and high crushing efficiency. Through the interaction between the rotor and the impact plate, the stone is rapidly broken and formed. The gap distance between the impact plate and the plate hammer is adjustable, which is suitable for the production requirements of various materials and various sizes.

Capacity: 30-800 t/h

Feeding Size: ≤500 mm

Power: 37-710 kW

Weight: 12 Tons

Application: Suitable for pressure 350Mpa various types of stone.

Lead Time: 15-30 Days.

Nickel-chromium hammer heads are strong, reliable, long service life, a full set of wearing parts can be replaced, and the production cost is low.

The high-speed rotor interacts with the counter plate, crushing at once, and having high efficiency.

The size of the discharge particle can be adjusted to meet the needs of various materials and different crushing specifications.

The impact crusher with the conveyor belt can build a fully automated production line to improve your production efficiency

| Model | Rotor D×L (mm) | Feed port size (mm) | Max feed size (mm) | Capacity (t/h) | Power (kw) | Weight (t) | Overall Dimension (mm) |

|---|---|---|---|---|---|---|---|

| PF-1007 | φ 1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 12 | 2330×1660×2300 |

| PF-1010 | φ 1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 15 | 2370×1700×2390 |

| PF-1210 | φ 1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | φ 1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | φ 1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 27 | 3180×2720×3120 |

| PF-1320 | φ 1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 34 | 3220×3100×3120 |

| PF-1520 | φ 1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 50.6 | 3959×3564×3330 |

| PF-1820 | φ 1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 83.21 | 4400×3866×4009 |

Impact Crusher is a kind of medium and fine crushing equipment using impact energy to break materials, suitable for medium hardness and brittle materials (such as limestone, coal gangue, concrete, etc.), widely used in mining, construction, metallurgy, chemical industry, road and railway construction and coal, cement and other industries

Applicable materials:

Mines and quarries

Limestone, granite, basalt and other ores, the production of construction sand aggregate

Construction waste recycling

Waste concrete, bricks, asphalt blocks are broken to generate recycled aggregate for use in road base or new building materials

Cement industry

Crushed limestone, clay, gypsum and other raw materials to meet the needs of cement raw material preparation

Metallurgy and chemical industry

Crushing coke, slag, phosphate rock and other industrial raw materials

Coal industry

Crushing of raw coal or coal gangue for power generation, brick making or filling materials

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.