Vertical Compound Crusher is also called Vertical shaft Sand Making Machine, with dry and wet material is not blocked, uniform strength, good grain shape, high yield characteristics, widely used in mining and construction industry of secondary crushing and sand making molding links.

Capacity: 20-180 t/h

Feeding Size: ≤120-190 mm

Power: 45-250 kW

Weight: 3-25 Tons

Application: Minerals with a maximum hardness of 6-8.

Lead Time: 15-30 Days.

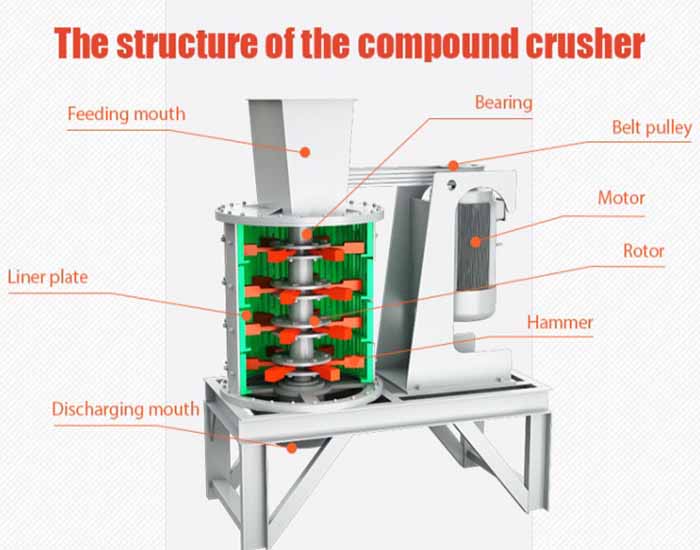

Cylinder door design can be opened quickly, easy to replace hammer head and deal with blocked material, convenient and simple maintenance.

The Vertical Compound Crusher has 4-8 sets of hammers, which makes sand efficiently according to different crushing needs, and the ore enters the bin for one molding.

The hopper is made of high-quality steel, wear-resistant and corrosion-resistant, and has a long service life.

Simple structure, easy operation, small footprint, higher crushing efficiency, low noise, safe and convenient maintenance.

| Model | Capacity (t/h) | Input Size (mm) | Discharge Size (mm) | Motor Power (kw) | Dimensions (mm) |

|---|---|---|---|---|---|

| PFL1000 | 20-40 | <120 | <5 | 45-55 | 2600*1400*1900 |

| PFL1250 | 30-60 | <150 | <5 | 75-90 | 2800*1600*2100 |

| PFL1500 | 50-100 | <180 | <5 | 132-160 | 3100*1900*2200 |

| PFL1750 | 80-150 | <180 | <5 | 185-200 | 3710*2360*2390 |

| PFL2000 | 100-180 | <190 | <5 | 220-250 | 4100*2660*2620 |

1. Construction industry

Concrete and mortar production

Vertical Compound Crusher can crush hard rocks (such as granite and basalt) into standard sand and gravel aggregates for the foundation and main construction of concrete structures such as high-rise buildings and bridges. Its finished sand grade is reasonable and the stone powder content is controllable, which significantly improves the strength and durability of concrete.

Recycling of construction waste

Vertical Compound Crusher can crush construction waste such as concrete blocks, bricks and tiles to generate recycled aggregates for road base or new buildings, reducing resource consumption.

2. Road and railway engineering

Highway and railway base material

Vertical Compound Crusher can be used to produce crushed stone and machine-made sand required for asphalt concrete, improve the compressive and wear resistance of the road surface, and is designed for high-speed railways and highways. The finished sand particles are cubic in shape, reducing the amount of asphalt and enhancing the density of the road surface.

Road maintenance and repair

Vertical Compound Crusher can process recycled aggregates on site, quickly prepare repair materials, and reduce traffic interruption time.

3. Mining and Metallurgy

Ore Crushing and Tailings Treatment

Vertical Compound Crusher is suitable for crushing high-hardness materials such as iron ore and gold ore, and can also convert mine tailings into construction sand.

Metallurgical Raw Material Processing

The ore after crushing by the Vertical Compound Crusher has uniform particle size and meets the requirements of smelting process.

4. Water Conservancy and Hydropower Engineering

Dam and Reservoir Construction

Sand and gravel aggregates produced by Vertical Compound Crusher are used to prepare anti-seepage and anti-freeze concrete to ensure the stability of water conservancy facilities.

River Management and Slope Protection Engineering

Vertical Compound Crusher can process raw materials such as river pebbles and granite to generate aggregates that meet water conservancy standards. The finished products can be used for dam reinforcement and ecological slope protection blocks.

5. Concrete Products and Industrial Applications

Prefabricated Component Production

The machine-made sand produced by the Vertical Compound Crusher can be used to prefabricate standardized components such as floor slabs and pipe piles to improve the efficiency of prefabricated buildings.

Preparation of glass and ceramic raw materials

The Vertical Compound Crusher can crush quartz sand, bauxite and other materials to meet industrial grade particle size requirements.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.