Box crusher aka Square box crusher has the characteristics of simple structure, easy maintenance, low price and high cost performance, and is often used for secondary crusher to break rocks into small cobbles.

Capacity: 70-400 t/h

Feeding Size: ≤600 mm

Power: 55-320 kW

Weight: 5000KG

Application: Suitable for pressure 300Mpa various types of stone.

Lead Time: 15-30 Days.

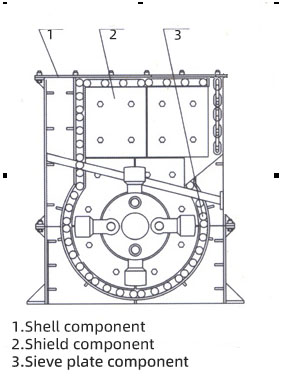

Box crusher is our company absorbs advanced technology at home and abroad, comprehensive jaw crusher, hammer crusher, impact crusher, snail crusher and other crusher advantages of the integration of stone breaking machinery. Large stones directly into the crusher, automatic feeding, directly the side length of 450-1200 mm material broken into powder to 80 mm particle size of ore, and no blocking machine, can also be used as a secondary crusher, mainly used in mining, cement, building materials, chemical industry and other industries.

The box crusher has a full discharge shape and a capacity of 70-400 tons per hour, and the finished products can be used in buildings, roads, airports and other construction.

The finished product rate is high, and the granular product accounts for about 85%, which fully meets the use requirements.

The hammer head, grate plate and impact plate are made of high manganese steel wear-resistant material, which has a longer service life.

The box crusher has a simple structure, is easy to unpack, and can quickly handle blockages and replace hammers.

The feed port is equipped with an iron chain barrier to prevent material from splashing during the crushing process.

Main technical parameters

| Model | 800×800 | 1000×1000 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

|---|---|---|---|---|---|---|

| Roller diameter (mm) | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Roller length (mm) | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Capacity (t/h) | 70-100 | 90-120 | 130-160 | 190-210 | 250-300 | 300-400 |

| Feedstock size (mm) | ≤600 | ≤800 | ≤900 | ≤1000 | ≤1000 | ≤1200 |

| For stone (Pressure 3000MPa various types of stones) | - | - | - | - | - | - |

| Power (kw) | 55-75 | 55-75 | 75-90 | 132-150 | 160-210 | 180-320 |

Box crusher is suitable for primary and secondary crushing of various materials with compressive strength below medium and upper hardness. It is especially suitable for crushing materials used in mining, building materials, chemical and metallurgical industries. The compressive strength of the crushed material is not more than 100 MPa, and the humidity is not more than 15%.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.