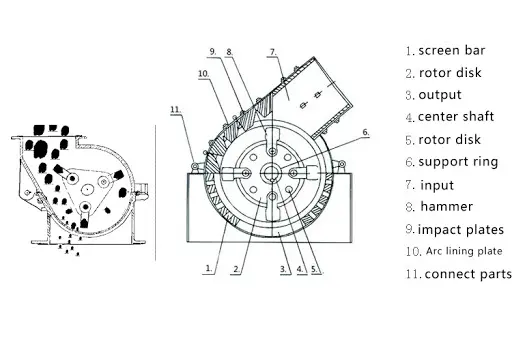

A hammer crusher is a robust industrial machine designed to crush and grind materials into smaller particles using high-speed rotating hammers. The equipment features a heavy-duty structure, adjustable output size, and high crushing efficiency, making it ideal for processing medium-hard and brittle materials like limestone, coal, gypsum, and ore.

Gradient: 1-3°

It is widely used in mining, cement, coal, metallurgy, and construction industries.

Feed size: ≤ 100-250 mm

Discharge size:≤ 10-19 mm

Power: 11-220 kw

Productive capacity: 5-180 t/h

Weight: 0.8-16.6 t

Rapid crushing with minimal energy consumption.

Reinforced steel body and wear-resistant hammers.

Suitable for diverse materials and adjustable output sizes.

Easy access to internal components for quick servicing.

| Specification | Capacity (m³/h) | Motor Power (kw) |

|---|---|---|

| PCφ400*300 | 5-10 | 11KW (4P) |

| PCφ600*400 | 10-22 | 22KW (4P) |

| PCφ800*600 | 18-40 | 55KW (6P) |

| PCφ1000*800 | 25-50 | 75KW (8P) |

| PCφ1000*1000 | 30-55 | 90KW (8P) |

| PCφ1300*1200 | 60-100 | 110KW (8P) |

Mining Industry: Crushing coal, ore, and minerals.

Cement Production: Grinding limestone, clay, and other raw materials.

Metallurgy: Processing metal ores and slag.

Construction: Breaking down concrete, bricks, and asphalt.

Chemical Industry: Pulverizing chemicals and fertilizers.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.