Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce rocks to smaller sizes for the next crushing stages. Jaw crushers are a popular alternative to primary gyratory crushers ,since they can process large amounts of hard material efficiently.

Applicable materials:

Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

Capacity: 3-200 t/h

Feed size: 120-1200 mm

Power: 5.5-280 kw

Weight: 0.8-122 tons

The gap between the jaws can be adjusted to control the size of the crushed material. This allows for customization of the output size.

Jaw crushers are designed to provide a high reduction ratio, meaning they can crush large materials into smaller particles efficiently.

Jaw crushers are built with a robust and sturdy design to handle heavy-duty applications and withstand the rigors of continuous operation.

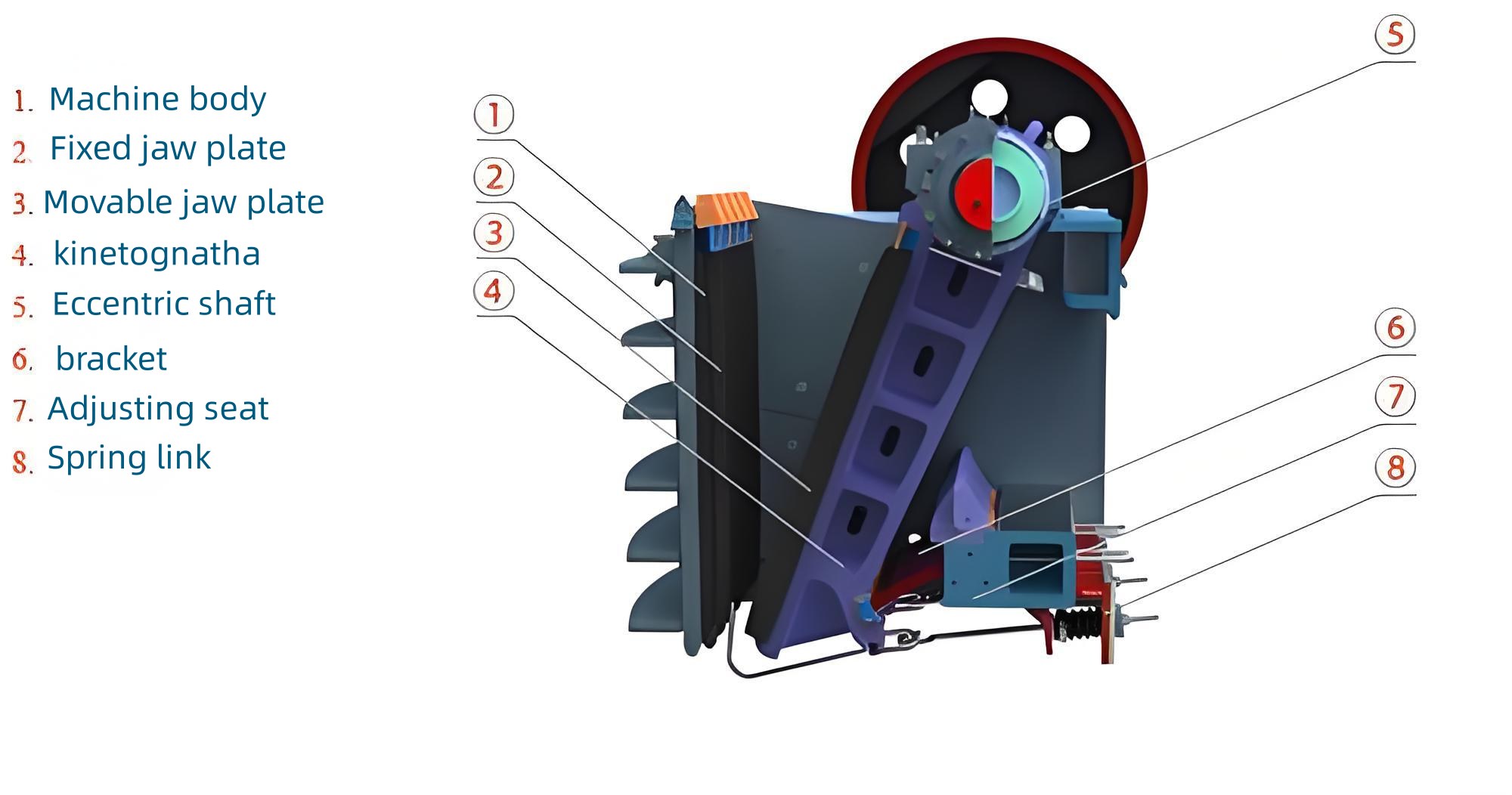

The design of the crushing chamber and the kinematics of the movable jaw contribute to efficient crushing, resulting in high productivity.

Jaw crushers are designed to optimize energy consumption. Advanced technologies, such as hydraulic systems and flywheel inertia, contribute to reducing power usage

Jaw crushers are available in various sizes and compact designs, making them suitable for both stationary and mobile applications.

Techspecs of Jaw Crushers

| Model | Feed in size (mm) | Max feed size (mm) | Discharge size (mm) | Capacity | Eccentric shaft speed (r/min) | Power (Kw) | Weight (t) | Overall dimension (mm) |

|---|---|---|---|---|---|---|---|---|

| PE-150X250 | 150X250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720*660*850 |

| PE-200X300 | 200X300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910*750*990 |

| PE-200X350 | 200X350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000*870*990 |

| PE-250X400 | 250X400 | 210 | 20-60 | 5-20 | 300 | 18.5 | 2.8 | 1300*1090*1270 |

| PE-400X600 | 400X600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730*1730*1630 |

| PE-500X750 | 500X750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980*2080*1870 |

| PE-600X900 | 600X900 | 500 | 65-160 | 50-180 | 250 | 75 | 17 | 2190*2206*2300 |

| PE-750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 250 | 90 | 29 | 2660*2430*2800 |

| PE-900X1200 | 900X1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380*2870*3330 |

| PE-1000X1200 | 1000X1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480*2876*3330 |

| PE-1200X1300 | 1200X1300 | 1000 | 180-300 | 400-650 | 220 | 200 | 62 | 4538*2984*3959 |

| PE-1200X1500 | 1200X1500 | 1020 | 150-350 | 400-800 | 180 | 250 | 80 | 4200*3300*3500 |

| PE-1500X1800 | 1500X1800 | 1200 | 220-350 | 450-1000 | 180 | 280 | 122 | 5160*3660*4248 |

| PEX-150X750 | 150X750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200*1530*1060 |

| PEX-250X750 | 250X750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380*1750*1540 |

| PEX-250X1000 | 250X1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560*1950*1390 |

| PEX-250X1200 | 250X1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140*1660*1500 |

| PEX-300X1300 | 300X1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720*1950*1600 |

| PEX-300X1500 | 300X1500 | 250 | 25-120 | 60-140 | 300 | 75 | 16.5 | 2920*1950*1600 |

| PEX-500X1500 | 500X1500 | 350 | 25-120 | 50-160 | 300 | 90 | 20 | 2360*2660*2105 |

| PEX-500X2000 | 500X2000 | 350 | 25-120 | 100-220 | 300 | 160 | 23 | 2360*3160*2105 |

<!--!doctype-->

River pebble, granite, basalt, iron ore, quartzite and other medium-hard hard rocks.

STCrushers provides high quality and reliable mining equipment customize manufacturing service for global customers, we design the production line according to the needs of the customer's processed materials and output, and realize fully automatic production from feed to discharge.

We have more than 20 years of experience in the production of large mining equipment.

We have an experienced production line design team to meet the processing needs of different materials.

We have two large workshops, a variety of processing equipment and machine tools.

The company strives to provide customers with preferential prices and payment methods to meet customer needs.

If you are looking for mining equipment such as stone crushers, ball mills, rotary dryer, rotary kiln and other equipment, feel free to contact us and our team will reply within 48 hours.