A customer from Saudi Arabia wanted to build a gypsum stone roasting production line for the manufacture of gypsum board, expecting to produce 10 tons per hour, using fuel oil and diesel as heat sources. However, he encountered problems with the entire production process, and could not solve the pre-treatment and post-roasting treatment of the materials, so he found STcrusher.

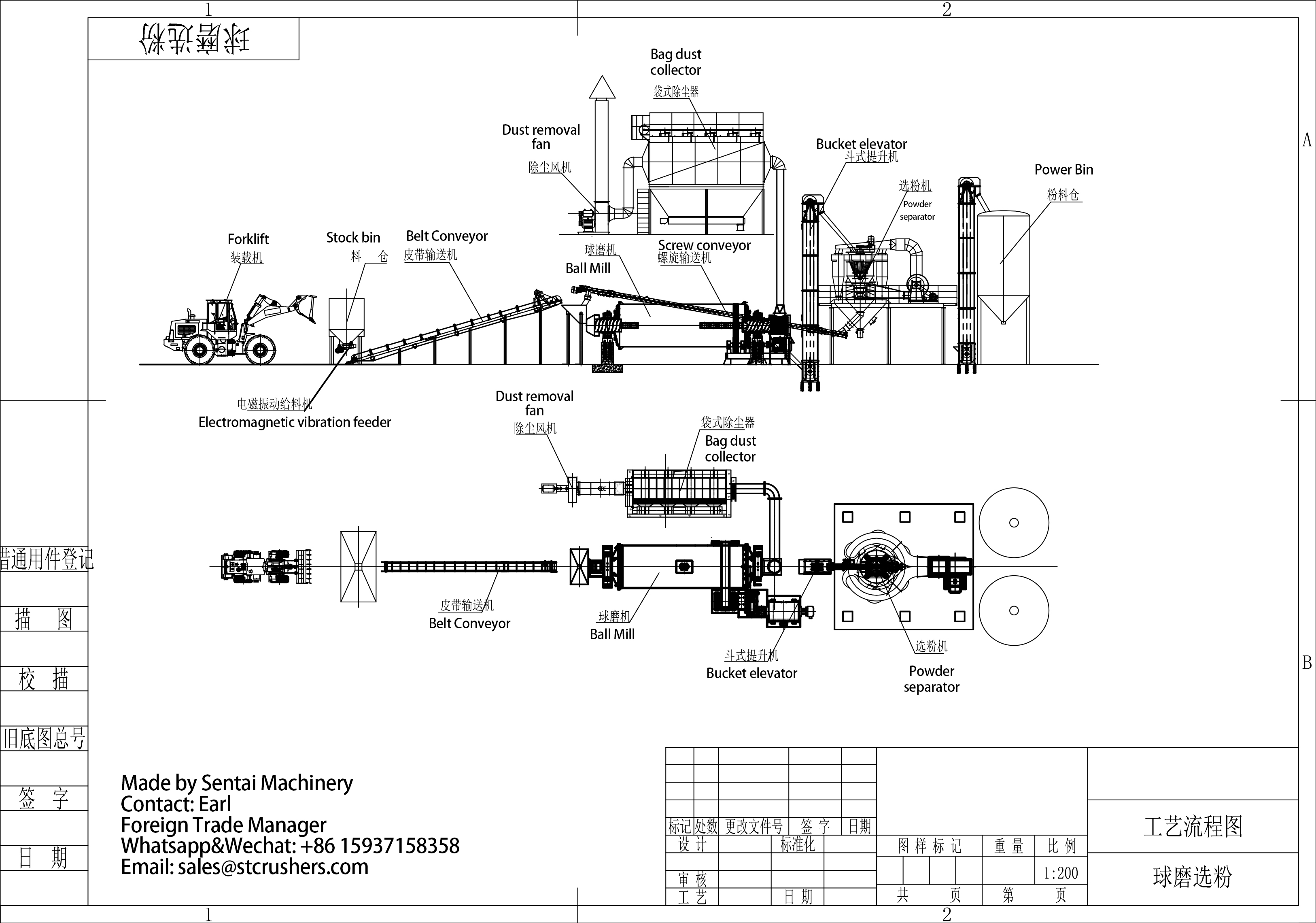

After understanding the customer's production needs, we immediately provided professional solutions. The entire production line consists of a grinding part and a roasting part. The material first enters the grinding part and is crushed into powder by a ball mill. Then the substandard materials are crushed again by a powder selector, and finally the powdered materials enter the powder silo.

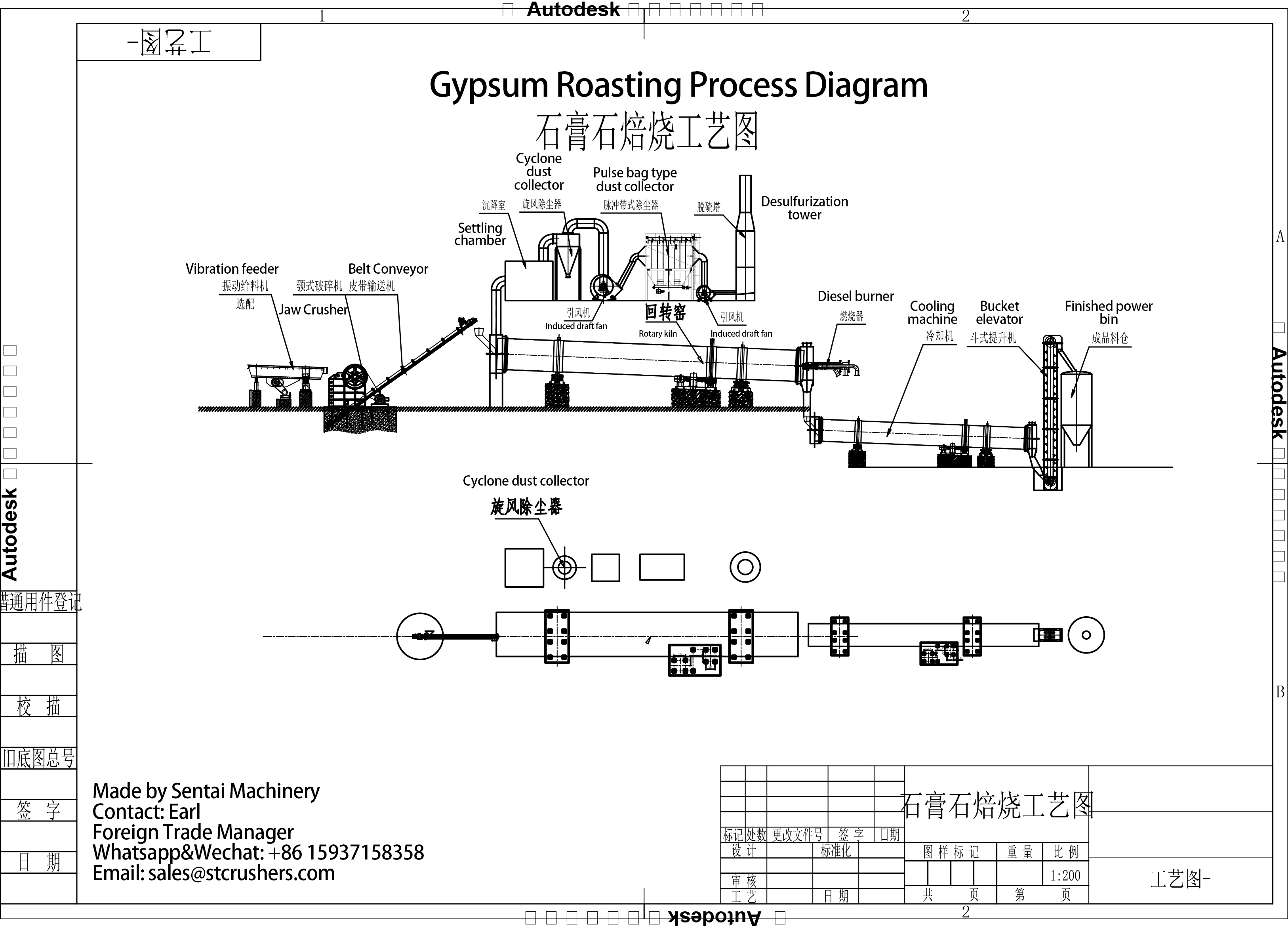

The material then enters a 2.2-meter diameter rotary kiln for high-temperature roasting. After being cooled by a cooler, the finished product enters the finished product silo and is packaged by the customer, doubling the cost and profit.

STcrushers provided on-site engineers to provide guidance on installation. After the equipment was debugged, the customer's workers were immediately trained on how to operate it. The customer was very satisfied with the whole set of services.

STcrushers' professional services fully meet customer needs. Whether it is equipment customization or on-site installation, choosing us will allow you to solve material crushing, drying and processing needs in one stop. The complete supply chain ensures that customers will never be disappointed.